A. Sampling

Collect the samples at the following quantities for ensuring

meaningful representation of the whole lot of feed / feedstuff

Min. sample size

Small particle type (milk, vegetable oils) 500 g

Intermediate particle type (ground meals, flours,

compounded feed)

3 kg

Small grains (wheat, rice, sorghum, ragi, barley etc.) 5 kg

Intermediate grains (maize, cotton seed / cake) 10 kg

Large grains (groundnuts / cake) 20 kg

Collect at least 100 subsamples from the whole lot. For eg. from a

truck of 100 bags of maize, collect 100 g maize from each bag to

obtain a total sample size of 10 kg

Get about 50 - 100 g subsample from the whole sample employing

either coning and quartering method (in a series of steps) or using

sample divider

The subsample thus collected can be directly subjected for analysis

B. Outline of Mycotoxin analysis

Sampling

Toxin extraction

(using organic solvents)

Clean-up

(To remove fat, impurities etc.)

Work up

Identification & Quantification

(TLC, HPLC, ELISA etc.)

C. Different methods of Mycotoxin analysis

C. 1. Thin layer chromatography (TLC)

It is the cheapest and most commonly used method. It makes use of

heterogenous equilibrium established during the flow of a solvent

(mobile phase) through a fixed phase (stationary phase) to separate ≥

2 components from materials carried by solvent (differential

migration).

Spotting the extract

Place between 5 - 20 μl of sample extract / standard as a small circular

spot (< 5 mm), 1 - 2 cm from the end of the TLC plate. Micropipette /

microcaps may be used for the purpose. Leave at least 1 cm gap

between two adjacent spots.

Developing the plate

Place about 50 - 100 ml of mobile phase (solvent) in a tank and keep

the plate at a slight angle with the spots little above the upper level of

the solvent. Due to capillary action, solvent moves upward on the

plate. Allow the solvent to travel at least about 8-10 cms.

Detection

Air dry the developed plate and view in a UV cabinet under either

longwave (365 nm) or short wave (254 nm) range to identify the

fluorescing mycotoxins. In case of mycotoxins which do not

fluoresce, spray the plate with suitable reagent to develop

fluorescence.

Resolving front value (Rf)

Each mycotoxin has its characteristic color of fluorescence under UV

light and a constant Rf value in a particular developing solvent

(Table 3). Rf value is computed using the formula,

Distance travelled by sample spot from the origin

Rf =

Distance travelled by solvent front from the origin

Confirmation

The presence of mycotoxin can be confirmed either by spraying the

plate with suitable reagents (like 50 % aqueous H2SO4, Triflouro

Acetic Acid etc.) or placing an internal standard right over the top of

the sample spot (superimposing).

Detection by Scanner

The fluorescence intensity of sample and standard spots can be

measured by using TLC Scanner / fluorodensitometer to avoid

possible human errors in comparison.

Table 3. TLC characteristics of mycotoxins

Toxin Rf * Color Color (UV) after

(UV) spray * *

Aflatoxin B1 0.31 Blue Pink

Aflatoxin B2 0.26 Blue Pink

Aflatoxin G1 0.23 Green Blue

Aflatoxin G2 0.17 Green Blue

Ochratoxin A 0.55 Green Blue

T-2 toxin 0.36 Yellow Blue

Zearalenone 0.78 Blue Yellow

DAS 0.33 Yellow Variable

Sterigmatocystin 0.85 Red-brown Yellow

*TEF : Toluene : ethyl acetate : formic acid ( 6:3:1 )

* *P - anisaldehyde

C. 2. Spectrophotometry

This is an extension of TLC method. The sample spots on the

developed TLC plate are scraped out alongwith the sorbent (silica gel)

and extracted with methanol for 3 minutes. The extract is filtered and

the absorbance of the filtrate is measured in a spectrophotometer

at 363 nm.

Reference :

Nabney and Nesbitt. 1965. Analyst 90 : 155-160.

C. 3. High Performance Thin Layer Chromatography (HPTLC)

This is an improvised version of TLC, where sampleapplication and detection of fluorescence intensity are fully automated

and carried out by using automated sample applicator (like Linomat

IV of Camag, Switzerland) and densitometer, respectively.

Mycotoxin levels less than 0.1 ppb can be detected by this method.

C. 4. Minicolumn method

A glass column of 20 cm length, 6 mm internal diameter withtapering end (2 mm) is packed serially from the bottom with glass

wool, calcium or sodium sulphate (8-10 mm), florisil (8-10 mm),

silica gel (18-20 mm), neutral aluminia (8-10 mm), calcium or

sodium sulphate (8-10 mm) and a cap of glass wool.

2 ml of final chloroform extract (in case of aflatoxin) is placed

in the column and eluted with chloroform : acetone (9 : 1). Aflatoxin,

if present is trapped as a band above florisil layer which can be

viewed under long wave UV light as a blue fluorescent band. This

method can be used as a qualitative test for rapid identification of

mycotoxin.

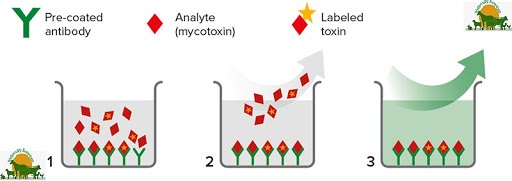

C. 5. Immuno assays

These assays are developed on the basic principle ofAntigen - Antibody reaction. Antibodies are highly specific to the

Mycotoxin - Protein conjugate (Hapten) used. Hence the results will

be highly specific.

Commonly employed immuno assays

Radio immuno assay (RIA)

Standard mycotoxin, labelled onto a radioactive compound like

Tritium is used. Mycotoxin levels as low as 2-5 ppb can be

detected. The disadvantages of this method include high cost,

difficulty in labelling, radio active waste disposal problem and

risk of handling.

Enzyme linked immuno sorbent assay (ELISA)

It has received great attention in recent times and has been the

most popular and widely practiced immuno assay method.

ELISA is rapid, more sensitive, highly specific and simple to

operate. It does not require any extensive extraction or cleanup.

Commercial ELISA kits

Various companies have been marketing commercial kits

which basically work on ELISA principle. These have gained

wider acceptance as considerable amount of time is saved on

antibody production. Sample is extracted with methanol : water

(60 : 40) or acetonitrile : water (50 :50) and the extract is

directly subjected to analysis.

Elisa tests are good for quick identification of

mycotoxins in feed samples, various tests are developed based

on Antigen - Antibody principle. Some companies which

produce ELISA kits are :

1. Neogen Corp,

620, Lesher place,

Lansing, Michigan 48912, U.S.A.

2. Vicam,

313, Pleasant St.,

Watertown, Massachusetts - 02172, U.S.A.

C. 6. High performance liquid Chromatography (HPLC)

It is highly sensitive and can detect upto 5 x 10-6 ppb level ofmycotoxin. Stainless steel columns (< 18) of 15 cm length and 4 mm

internal diameter, packed with silica gel (particle size - 5 microns) are

used. Sample is first extracted with suitable solvent (generally 60 %

aqeous methanol) and the extract is cleaned - up.

This purified extract (20 μl) is injected into the column and the

eluent (generally a mixture of methanol, water and acetonitrile) is

passed at a flow rate of 0.75 ml / min and at a pressure of 3000 psi.

The eluted toxins coming out of the column are detected and

quantified by fluorimeter.

The columns may be either normal phase (polar stationary

phase) or reverse phase (polar mobile phase) type. The latter type is

most commonly used.

C. 7. Bio - assays

Mostly are useful as confirmatory tests. Toxin extract isinjected as a single dose into stomach (day-old duckling bioassay,

guinea pig bioassay), fertile eggs (chick embryo bioassay) or into skin

of rabbits (skin bioassay). Presence of toxin is confirmed by noticing

pathological changes or mortality.

Safety precautions in mycotoxin analysis

Carryout the mycotoxin analysis in a separate work area in the

laboratory

Cover the bench top with non absorbent material

Solvents used are highly inflammable. So avoid using electric stoves,

bunsen burners etc.

Do not stock the solvents in larger quantities

Wear protective clothing, gloves and mask to minimise the risk of

inhalation / contact with hazardous mycotoxins

Some of the solvents (like benzene, chloroform) are toxic. Avoid

direct skin contact with them

Any spillage should be immediately mopped-up with cotton. Such

cotton should be incinerated

After completing the work, decontaminate the area with 4 % sodium

hypochlorite solution

Decontaminate the glassware by soaking for atleast 2 hours in 1 %

sodium hypochlorite solution

Spray the TLC plate with reagent only in a fume cup-board / spray

cabinet

At the UV cabinet, always view the TLC plate only through the UV

filter

Avoid eating, drinking and smoking in the laboratory

Keep the lab well ventilated using exhaust fans